Understanding what goes on inside a slurry pipeline—an elaborate system involving fluid dynamics, hydraulic pressure and various solids, liquids and gases in suspension—is a complex matter. Research in a laboratory setting helps develop pipe flow models that are used to design and operate pipelines reliably, safely and efficiently.

A key challenge of this type of research is obtaining information about the contents moving through the pipe without disturbing the flow.

studying flow behaviour

In mining operations, ore or waste rock is often crushed and mixed with water at some point in the extraction process. Frequently, this mixture, known as a slurry, is transported by pipelines over long distances.

These slurries contain particles of sand, rock and clay that may accumulate inside or erode the pipeline, affecting its overall efficiency and lifespan. Getting a clear picture of the solids concentration distribution in the pipe is crucial to building models to predict flow behaviour.

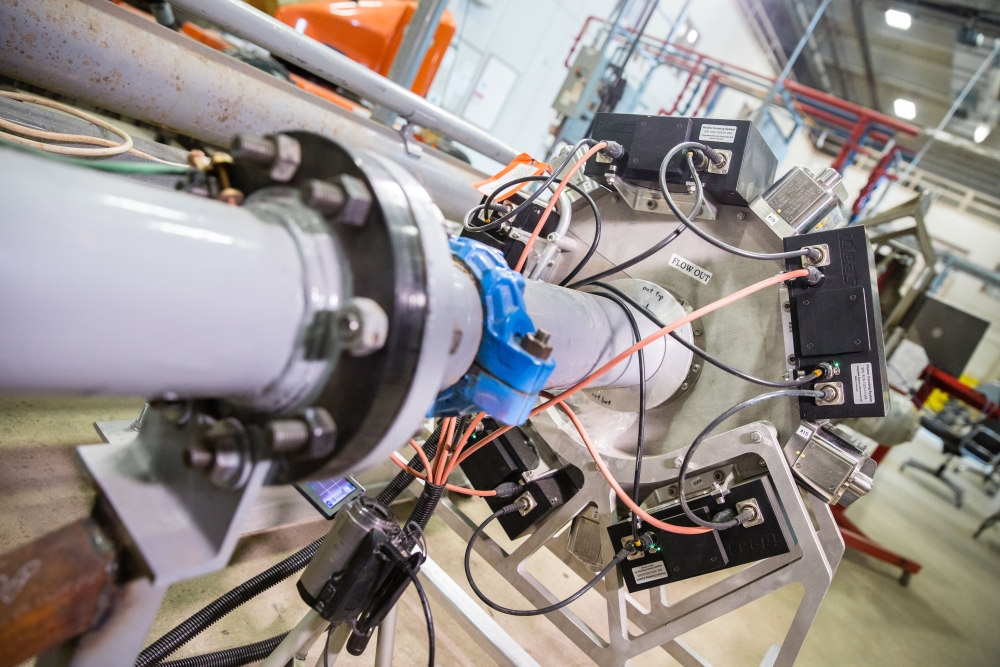

At SRC’s Pipe Flow Technology Centre™, diving into the physics and technical matters of fluid mechanics is second nature. And now, they’ve acquired a tool that stands to make their job much easier and more interesting: the Gamma Ray Tomography (GRT) unit.

real-time images of pipeline contents

One of the only units of its kind in the world, SRC’s GRT unit uses multiple gamma-ray sources and sensors to produce real-time images of the density of the pipeline contents at data acquisition speeds of up to 100 frames per second.

The new unit is used to reconstruct a high-resolution image of the solids concentration distribution across the pipe cross-section. The high frame rates allow engineers and scientists to visualize the concentrations of materials flowing through the pipe, almost like watching a movie.

What makes the GRT unit especially unique is that it’s the first of its kind to be used for studying slurry pipeline flows.

Knowing how materials are dispersed within the pipeline is critical to properly modelling slurries. With the clarity the GRT unit provides, SRC’s experts get a better picture of how particles are positioned in the slurry, flowing through the pipe both laterally and vertically. The information generated helps build more accurate predictive models, which helps engineers to size pipelines and determine the energy requirements to pump materials safely and efficiently.

Improving the accuracy of these design decisions has the potential to save industry millions in operating and capital costs, as well as reduce environmental risks.

The GRT unit is not just for slurries, however.

How the GRT unit can be applied in other pipeline flows

Other multi-phase flows—mixtures of gas and liquid or froth—that vary rapidly and dynamically in pipeline flows can be observed and characterized. The GRT unit also opens new avenues for testing these turbulent flow regimes which have complex flow patterns in the pipe and are not very well understood, although they’re common in processes within the mining, mineral processing and oil and gas industries.

Another application involves thickened tailings settling slurry pipelines, which can sometimes operate in ‘laminar flow.’ This is an area of slurry pipeline research that is not very well understood.

SRC is leveraging the GRT technology to study laminar flow and develop flow models to assist engineers designing slurry pipelines for laminar flow operation. Thickened tailings operations where laminar flow may be present are becoming more common as industry strives to improve dewatering to reduce tailings storage volumes, enhance water recycling and reduce the environmental footprint of mining operations.

The GRT’s capabilities can be applied to new challenges faced by the mining and oil and gas industries to enhance their operations and improve their environmental performance.