This blog post is the first installment in a two-part series about the history of alternative fuels vehicle work at SRC, focusing on the 1980s and 90s. In the second post, we will take a look at the work done from 2000 on.

Fossil fuels are increasing in demand, but supplies are diminishing. As a result, there is broadening interest in alternative forms of fuel for transportation needs. A growing number of people believe alternative fuels will have an expanded role in the cars and trucks of tomorrow.

Using alternative fuels and advanced vehicles, instead of conventional fuels and vehicles, helps lower vehicle emissions that contribute to smog, air pollution and global warming. Additionally, many alternative fuels don’t come from finite fossil-fuel resources and are sustainable.

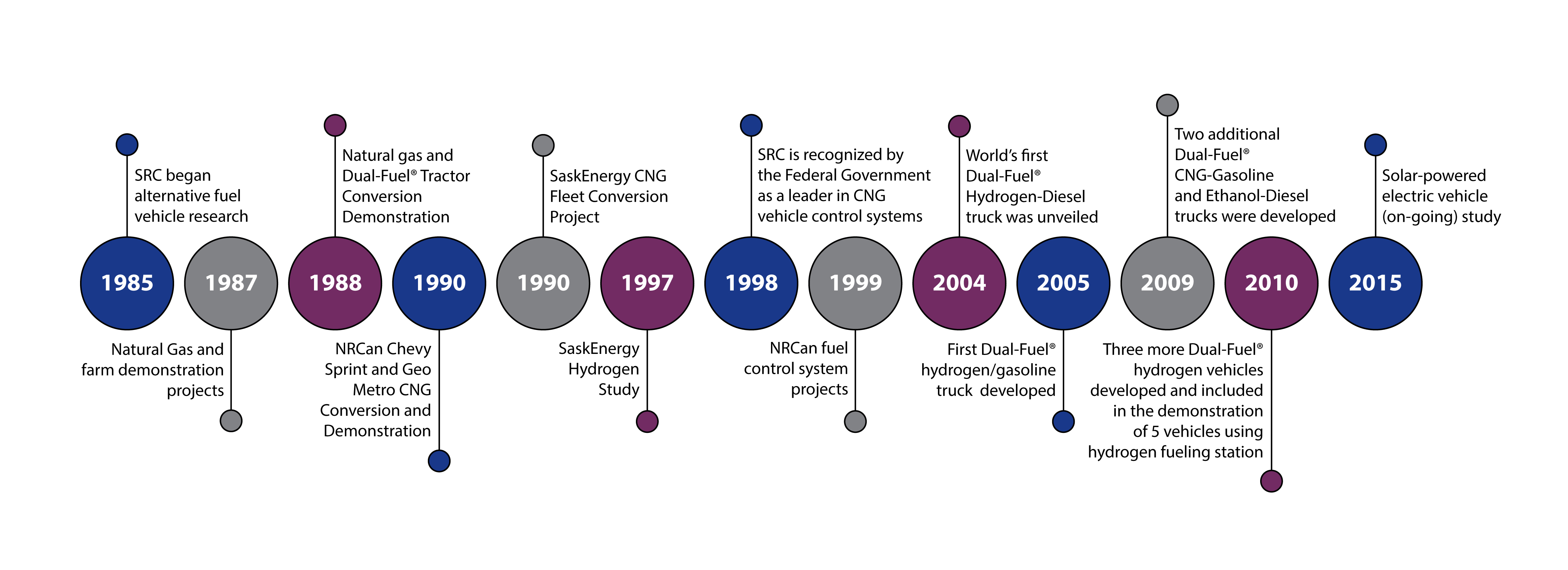

SRC is one of the pioneers in the field of alternative fuel vehicle work and has a long history conducting research and development in the area since 1985. This work was initially driven by projected fossil fuel shortages from the 1980s to 2000, then later by improved tailpipe emissions and worries about global warming.

Over the past 35 years, various vehicles were adapted successfully to operate on natural gas, hydrogen and ethanol using microprocessor control. SRC’s journey into alternative fuels has been full of successes, some failures and even some firsts.

The 1980s: The Early Years

In the 1980s, SRC began its journey into researching alternative fuel vehicles with a series of projects funded by the Saskatchewan Ministry of Agriculture. The projects involved developing and demonstrating compressed natural gas (CNG) technologies as a way to provide cost-efficient, clean burning fuel for farms.

SaskEnergy started supplying about 40,000 farms with natural gas, and there was a desire to learn to what extent natural gas could be used to power farm vehicles. Natural gas was seen as an alternative fuel that burned clean, and was already widely available in Canada and in many countries, and provided heat for homes, businesses and industrial purposes.

Over the course of a year, SRC converted five pickup trucks to CNG and developed several on-farm CNG fuelling stations. In the demonstration phase of the project, which lasted two years, SRC worked with several Saskatchewan farmers who were able to use the new technologies to help run their farm operations more efficiently.

SRC also developed a natural gas-fuelled tractor based on a Deutz 7110. Two additional tractors, a White 2-180 and a John Deere 4440, were also adapted to operate on either conventional diesel fuel or a blend of diesel fuel and natural gas. The blend varied between 0 and 80 per cent natural gas depending on the engine speed and load on the tractor. However, the average substitution rate for using the blended fuel was about 50 per cent for the White 2-180 and 29 per cent for the John Deere.

All three of these tractors were used on a regular basis by local farmers to run their operations.

Many years later, in 2008, the mono-fuel Duetz tractor was converted to operate on 100 per cent ethanol fuel, rather than 100 per cent natural gas. It was demonstrated in various parts of Saskatchewan and Alberta before being transferred to the Pound-Maker Feedlot & Ethanol Plant in Lanigan, Sask. for commercial use.

Overall, these projects successfully demonstrated that:

- Natural gas could be used as a fuel to power farm trucks and tractors.

- The fuel cost of natural gas could be much less than diesel fuel, and the operation of farm trucks on natural gas could be economical if the truck can be fuelled at a centralized fuelling station.

- The cost of storage tanks on tractors and fuelling facilities on farms resulted in long payback periods (longer than 18 years) which did not provide for a strong business case for farmers.

These projects all paved the way for the development and demonstration of natural gas, hydrogen, ethanol and electric vehicles in the province over the next 25 years.

The 1990s: When Things Really Picked Up

In the early 1990s, SRC’s work in alternative fuels extended to other vehicles and other fuels. This started with the conversion of several Chevrolet Sprint and Geo Metro vehicles to natural gas through a project funded by Natural Resources Canada (NRCan) and SRC.

The first two vehicles, Chevrolet Sprints, were developed to meet ultra-low emission vehicle standards through a collaboration with Suzuki Japan and General Motors Canada (GM). Software was provided to SRC to reprogram the electronic control units for natural gas use. Emission tests conducted at Environment Canada in Ottawa, ON showed huge benefits of reducing tailpipe emissions with natural gas. Low emission standards, which are now common for modern gasoline-fuelled vehicles, were more of a reach back then as the technologies now in place did not exist in the 1990s.

In the next phase of the project, SRC successfully developed the vehicle control system on a Geo Metro for natural gas use. This project then moved into a demonstration stage that included small fleets of Geo Metros in Ottawa, Edmonton and Vancouver that were used as government, utility and delivery vehicles for several years.

Due to the success of this project and other work, by 1998, SRC was recognized as a major player in the development of natural gas vehicle control systems in Canada and around the world. An example of this was the overseas Geo Metro display in Cologne, Germany that highlighted SRC’s work in this area.

In the mid-1990s, SRC also assisted SaskEnergy with the conversion of a fleet of roughly 60 utility field trucks to natural gas, along with the installation and maintenance of six fuelling stations. Throughout this multi-year project, SRC provided technical support, training, conversion work, certification and maintenance to SaskEnergy.

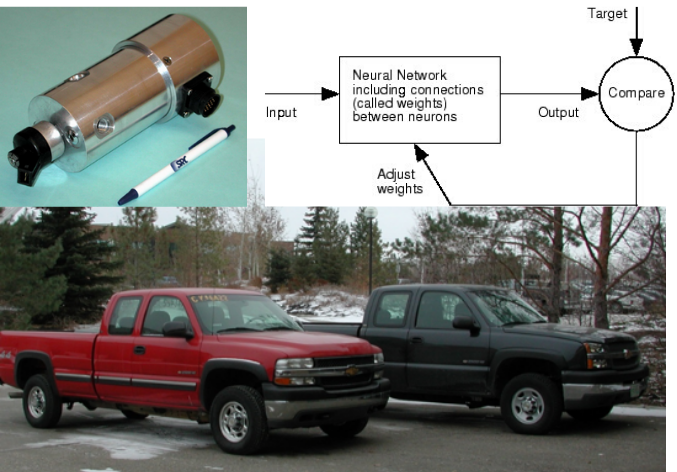

In 1997, SRC began to examine hydrogen as an alternative fuel for transportation. Studies related to hydrogen vehicle development and demonstration were conducted for Precarn, Gas Technology Canada, NRCan, SaskEnergy and the Government of Saskatchewan. This led to additional development of hydrogen-related products and vehicles, including fuel control systems, electronic pressure regulators and storage tank diagnostic systems.

SRC also worked on developing neural control systems for natural gas and fuel cell vehicles during this time. In addition to hydrogen vehicle technology, storage tank diagnostic systems were developed that could predict gas leaks from storage tanks before a break occurred. These projects were funded by NRCan, Precarn, Gas Technology Canada and SRC. Although the neural control technology was demonstrated in the lab, it was never featured in a public demonstration.

For all these vehicle conversions, high-pressure storage tanks (3000 to 5000 psi) were needed to contain the natural gas, along with pressure regulators and fuel control systems.

During the next decade, SRC expanded its previous work on natural gas vehicle conversion to develop and demonstrate a variety of other alternative fuel vehicles, including extensive work related to hydrogen as a fuel. More information on these exciting years to come in Part Two of this blog series.