With over 75 years of knowledge and expertise, SRC offers a range of services to meet the ever-evolving needs of Canada’s mining industry. SRC is growing its sensor-based sorting (SBS) capabilities to offer new services that help companies adopt ore sorting technologies — offering a variety of benefits including reduced processed waste and increased mine life.

SBS is a collection of technologies that separate ore particles or parcels of ore/waste based on mineralogical differences that sensors can detect.

“It provides another tool in the toolkit of mineral processing to remove waste rock or concentrate certain ore types to make the process more efficient,” says Mike McCubbing, Manager of SRC’s Diamond Services team.

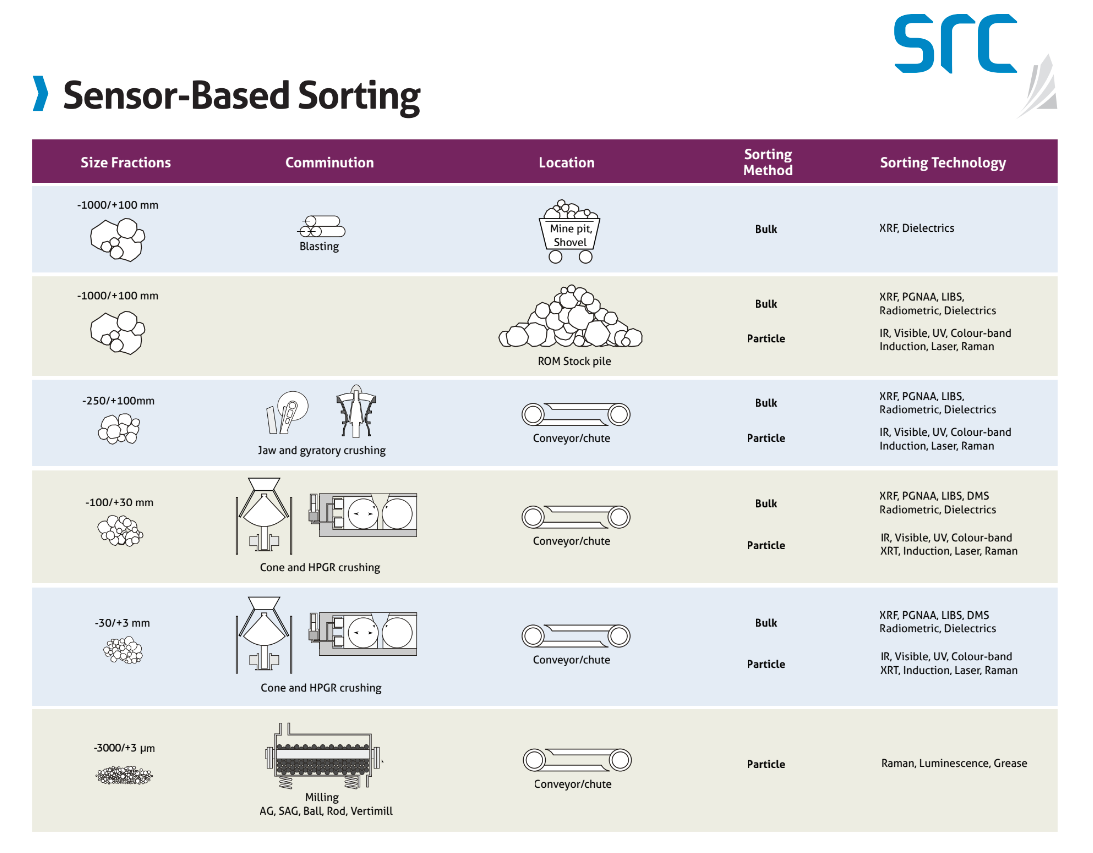

Particle sorting (also called ore sorting) separates coarse ore particles (10-100 mm) using sensors and mechanical separation using air ejectors. Whereas Bulk sorting detects the characteristics of whole ore particle parcels and can then separate these parcels from each other with a range of separation techniques, such as deviation of a conveyed feed on a belt.

Part of a long history of sorting technologies

Sensor-based sorting technologies have been in use for nearly one hundred years.

American inventor, Andrew Sweet, first filed a patent in 1926 for technologies that could separate ores using sensitive sensors. These sensors picked up changes in colour or the amount of light reflected from different minerals and metals.

Over the past decades, advances in SBS technologies began to rapidly commercialize, increasing the speed and accuracy at which sensor data is processed. This has enabled near real-time and automated separation and has made it a valuable tool for the mining industry.

SRC’s Diamond Laboratory has been using sensor-based technologies like luminescent sorting for decades.

“We have developed a lot of expertise in sensor-based sorting through other areas of our business,” says Lucinda Wood, Business Development Director for SRC’s Mining and Energy Division. “The diamond industry has been using sorting for a long time and we’ve expanded our capabilities around testing and operating sorting machines through our services.”

Over the past few years, the lab has adopted X-ray transmission (XRT) sorting technologies, which sort minerals by their unique atomic signatures.

“Sensor-based sorting technologies are evolving and SRC’s services will continue expanding in order to provide solutions for the future needs of the mining industry,” says McCubbing.

Creating a centralized source for sorting services

From sensor-based mineral characterization to pilot testing, SRC provides the mining industry with a variety of solutions for all stages of production, including exploration, to design, operations and brownfield expansions.

“We provide geochemical and mineralogical data for mining and exploration companies for many different commodities, such as uranium, gold, base metals, potash and rare earths,” says Rob Millar, Manager of SRC Geoanalytical Laboratories.

SRC has designed a testing regime to assist industry clients with choosing the right sensor-based sorting technology for their needs. The regime starts with sensor-based mineral characterization, then targeting and modelling, and finishes with pilot-scale testing.

SRC’s full suite of minerals liberation sorting services is based on expertise and technologies from across its facilities, such as SRC Geoanalytical Laboratories, Diamond Laboratory and Mineral Processing. This creates a “one-stop-shop” that serves a mining company’s sorting needs for any ore sorting technology.

Stage 1: sensor-based mineralogical characterization

The first stage, a specialized sensor-based mineralogical characterization service, assesses the type of technology and the amenability of ores to SBS technologies, based on the specific mineralogical characteristics of each ore. This allows companies to determine the optimal sensor technology at the optimal size and the information will eventually lead into modelling and total circuit design for processing these ores.

“Mineral characterization is the process of identifying, measuring and quantifying a mineral’s response to different sensors,” says Jane Danoczi, a Senior Process Engineer in SRC’s Mining and Energy Division. “With that information, you can identify what sensors will work with what ore.”

Danoczi is responsible for mineral characterization, which measures an ore’s unique qualities to evaluate how it responds to different sensors.

The distinct physical and chemical compositions of ore elicit different responses from different sensors, so a strong understanding of individual ore mineralogy is crucial to the successful adoption of SBS technology.

It is not only important to understand the mineralogy and sample grades, but also the textures of these minerals, the volumetric proportion of the minerals relative to others at different sizes and the levels of dissemination and whether they are heterogenous at certain size fractions and can be sorted.

SRC has the knowledge and expertise to assess the viability of sorting options and can develop custom-made sensor-based solutions for industry.

“With sensor-based sorting, you have to look at each fragment or particle and its complexity to see how to sort, but now we have a metric that can quantify this complexity and predict how it will respond to a sensor,” says Danoczi.

Using the Homogeneity Factor™ method developed by Danoczi’s team, the sortability at different size fractions by different sensors can more rigorously be determined in a methodological way.

This unique method assesses a particle’s complexity by rating it on a scale between positive 100 and negative 100. The higher the value, the easier the ore particle is to identify and sort. A low value like -90, for example, means the fragment is not homogenous with respect to the target mineral assemblage and will be more difficult for the sensor to sort.

These results lead to potentially different sorting options – based on different target minerals (not only desired metal, but also waste or associated minerals) – that can be successfully detected by sensors at sortable size ranges.

stage 2: Targeting and modelling

The next stage — targeting and modelling — helps clients decide on a desirable sorting strategy (i.e., which mineral, which size and which sensor) and then create a semi-empirical model with sorter data and start scaling up the testwork to develop.

Clients can use the valuable modelling information to test out various scenarios in the design phase for their operation. The model is developed by SRC experts through sorting first and includes inspection tests, models and algorithms.

stage 3: Pilot testing

The final stage — pilot testing — allows industry clients to obtain refined algorithms and an understanding of sorting yields and recoveries, as well as general performance of the full circuit.

This phase is important in determining the feasibility and capital costs of a sorting project.

High-tech solutions for economic and environmental challenges

If applicable, sensor-based sorting technologies can address many of the economic and environmental challenges faced by the mining industry, decreasing targeted energy costs and lowering emissions.

“Sensor-based sorting is a reliable and efficient way to upgrade or remove waste from further downstream processing,” says Wood. “If you can reduce the amount of material going to the mill, that reduces energy costs and tailings at the back end of the process.”

While the wide assortment of technical options can seem daunting, SRC can help mining companies navigate their sorting options by offering technological insight and processing expertise.

SRC also helps companies navigate the testwork needed to identify and optimize sorting applications. Based on the need for common testwork methodology, SRC is at the forefront of developing standardized methods to assist companies and other stakeholders, such as consulting companies, with this.

“Our role is to take this technology and evaluate its effectiveness in different mining applications,” says McCubbing.

An interdisciplinary approach for reliable results

SBS technologies rely on the integration and cooperation of many specialties.

“Sensor-based sorting requires a mixed discipline team,” says Danoczi. “Our team includes geologists, minerologists, physicists, minerals processing engineers and chemists, as well as people that work on algorithm development and artificial intelligence.”

SRC’s interdisciplinary team works together, assessing how different minerals respond to different sensors. They use their diverse knowledge and skills to identify which technologies are appropriate for the ore in question and understand how to test for, operate and design it into circuits.

The complexity of sensor-based sorting brings some challenges to the table, including finding ways to incorporate the technology at existing mines.

“The wide array of technologies can be challenging, but it is SRC’s role to evaluate the right tools for industry needs,” says McCubbing.

Danoczi says that with declining ore grades and more complex mineralogy, industry is starting to recognize the potential of SBS.

“Clients are seeing the necessity for sensor-based sorting to actually get their ore out of the ground or stockpiles and process it efficiently,” says Danoczi.

Benefits for industry and the environment

From XRT to near infra-red (NIR), colour and laser scattering, SRC can provide sensor-based sorting testing solutions that help industry select sorting applications to upgrade their ore and reduce waste.

“Sensor-based sorting reduces the energy required to process ore, the water requirements, the reagents and the overall carbon footprint,” says Danoczi. “With sensor-based sorting you benefit both the mines and the planet.”

By providing custom services and detailed data, SRC can help clients increase the value of their ore by optimizing the adoption of sensor-based sorting technologies, while reducing the environmental impact of their operations.